PDCA Cycle and OODA LOOP

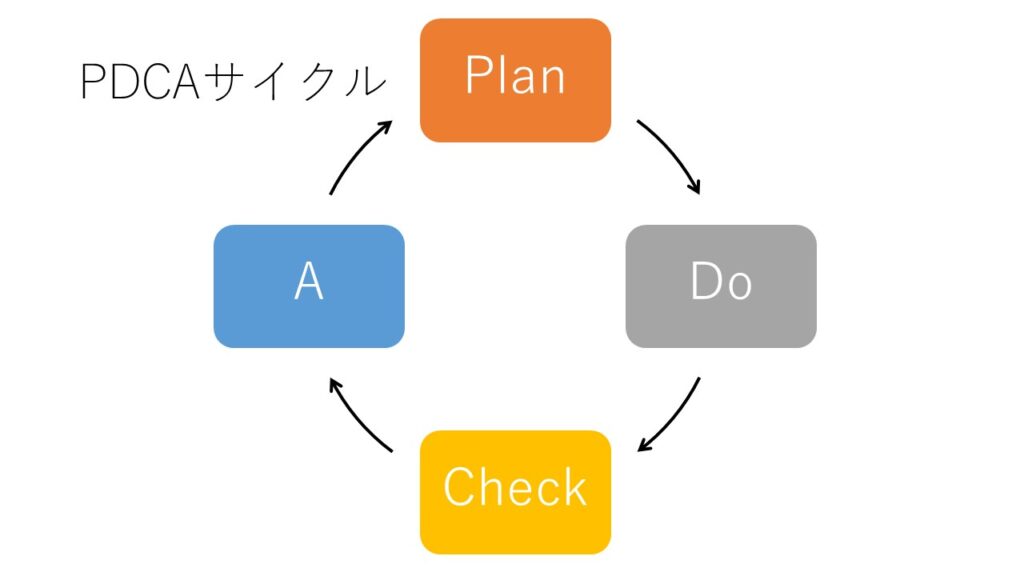

OODA LOOP is often confused with the concept of the PDCA cycle. The PDCA cycle consists of four stages: P (Plan), D (Do), C (Check), and A (Act), mainly used in quality management in factories and other fields to continuously improve operations.

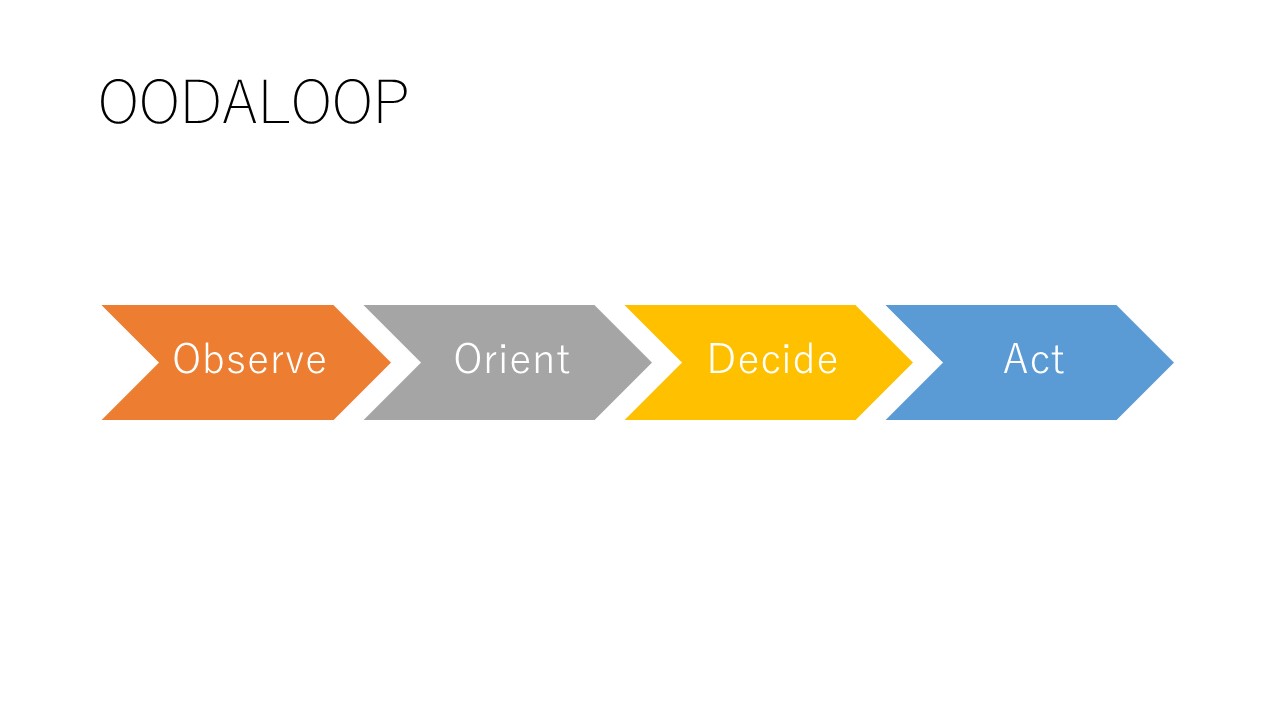

When explaining OODA LOOP, a common question is, “How is PDCA different from OODA LOOP?” In a nutshell, PDCA is a way of thinking during “peacetime,” while OODA LOOP is a way of thinking during “crisis.” This article will make the clear differences between these two concepts, enabling you to use them effectively.

What is the PDCA Cycle?

The PDCA cycle is a thinking method proposed by Dr. William Edwards Deming, an American statistician, in 1950. It is widely used in Japan as an effective method for business management.

First, let’s look at what the PDCA cycle is and its definitions:

P: Plan means setting goals and planning to achieve them.

D: Do is taking some action based on the plan.

C: Check involves evaluating and analyzing the success/failure factors of the actions taken based on the plan.

A: Act means considering measures to improve future actions based on the analysis results. These measures are used in the next planning phase.

To effectively implement the PDCA cycle, it is necessary to carry out the processes of evaluation (Check) and improvement (Act) accurately.

In the evaluation (Check) stage, you need to assess how much progress has been made compared to the plan and analyze the factors contributing to success or failure of the actions taken. Here, you must identify issues by breaking down the problems into manageable levels, in other words, “challenges.”

In the improvement (Act) stage, you need to clarify the “challenges” and develop measures to address them. It’s essential to avoid simplistic problem-solving approaches like “cause and solution.” If these two processes are neglected, the PDCA cycle will not work effectively, and the penetration of the flawed PDCA cycle is a significant problem.

However, there are few people who know that there is another problem with the PDCA cycle, namely, that it has a “fundamental deficiency.” This deficiency is that the PDCA cycle has a “very low ability to deal with uncertainty.” As mentioned earlier, the PDCA cycle is a thinking method that involves planning based on careful information collection and time to create the plan. If the surrounding situation does not change significantly, and you can gather information meticulously, the plan is likely to be realized. The PDCA cycle is considered a way of thinking during “peacetime” for this reason.

However, what we will face in the future is unpredictable situations. Just as Clausewitz introduced the concept of the “fog of war,” the battlefield is chaotic, and much of the information obtained is often incorrect. The situation around you changes moment by moment. In such circumstances, is there time to leisurely collect information and create plans? If you try to implement the PDCA cycle in a highly uncertain modern society, information gathering alone will take time. The information obtained is inaccurate, and it’s outdated.

As a result, the plan will inevitably lag behind the opponent. Once the plan lags behind, it will lead to further delays in decision-making and action, becoming a fatal disadvantage. No matter how many high-performance items you have, if you are lagging behind the opponent, you won’t be able to win.

コメント